This past week I learned what a clock spring (also known as spiral cable) is. For the past several decades I have been content with my ignorance, but not today!

As I may have mentioned in past updates, I have been regularly commuting to work, something I was missing the past year and a half. One of my colleagues has been joining me in the office (making two out of a team of around thirty that made the decision to go into the office) and we tend to go off to lunch. While on one of these lunch runs, I decided to drive Project CELICA and ran into a scenario where the person ahead of me was waiting for a certain shade of green, not driving while the light said “go.” I go to hit my horn to wake them up from their daze or remove their distraction, and was upset to find that my horn did not work. This was sad news as I believed I was at a place with Project CELICA where I could enjoy my peppy little 2ZZ-GE instead of taking it apart to clean this and repair that. No such luck!

So after conferring with my colleague, I got to work troubleshooting and learning all I could about car horns. Essentially, all the car horn is is a very simple electrical circuit between the car’s battery, a switch, and a two lead horn. There is a little extra leg in the circuit to accommodate the ECU for car alarms and the like, but aside from that, the switch sits behind the steering wheel, and when I push down on the wheel, the circuit is completed and the horn is expected to sound. This means any part of this system could be the problem, from the circuit, to wiring/components, or even the horn itself.

So when I press down on the steering wheel, the horn does not sound. Where do I start? My colleague forwarded me to a relay and a fuse that were located under the hood. These are excellent spots to start as they are simple to test and will provide additional information based on their testing results. Relays are an electrical component that I admit I was not as familiar with given my experience in low-voltage electronics, but the logic behind them made sense: the relay is essentially an active switch that closes when electrical signal is sensed. Fortunately, I already knew about fuses given my prior experiences working on car stereos.

In this case, the relay was waiting for the circuit to close from the battery back to ground through the switch behind the steering wheel. When that circuit closes, the relay closes the circuit from the battery through the horns (as there are two horns) to ground. The fuse is just sitting there in case there is a short through that circuit in order to prevent fire hazards.

I located the fuse and visually inspected it. It did not appear to be breaking the circuit. As a secondary test I also swapped the fuse with another identical one and the result did not change. This information told me the fuse was likely fine. Similarly, I swapped the relay with another relay under the hood and the result was the same–the horn still failed to sound.

An interesting tidbit that I tested after reading forums was to press the panic button on my keyless entry. The horns began blaring as well as the lights flashing. If these are the same horns that should sound when I press the switch, that takes a large chunk of my circuit out of the picture. The alternative would be that the panic button had its own dedicated horns, which didn’t appear to be the case in this instance.

I continued with the assumption that the horns are OK as well as the fuse and relay. All of the previously obtained evidence point that direction. The issue appeared to be upstream from the relay towards the steering wheel. This could be wiring, the switch itself, or this new piece which I read about called the clock spring.

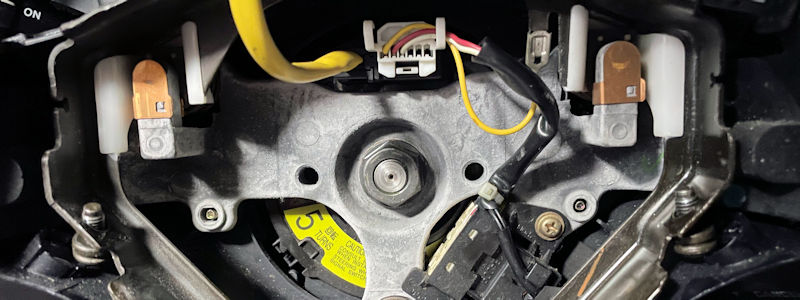

When the driver turns the steering wheel, any wires attached to it will naturally rotate with the wheel. Over time this can lead to fatigue and eventual break in the wiring. This can impact connectivity through the steering wheel which can include cruise control, radio functions, voice control, airbags, and of course, the car horn. To prevent against early wear of these wires, automotive engineers introduced what is called a clock spring, which is a little device with a ribbon cable of electrical leads designed to adjust with the steering wheel and maintain electrical continuity for these steering wheel mounted electrical functions.

In the case of this Toyota Celica, the only components that the spiral cable support are the car horn and the airbag since my car does not have cruise control. I ran on the assumption that if the clock spring had failed, both the airbag and horn would be nonfunctional. In my case, the horn didn’t work, but the airbag did. Therefore, I was looking at the switch in the steering wheel as the problem.

The repair manual had instructions about how to test the switch in the steering wheel. Basically, it stated that when I pushed down on the switch to complete the circuit, I can test continuity to electrical ground. While I thought I was testing, I actually wasn’t because you have to disconnect the chassis ground from the battery in order to prevent the airbag from going off while you are working on the steering wheel. I wasn’t thinking things through so I was attempting to test continuity to battery ground from the chassis while I had it disconnected. I guess I’m a dope for that one.

Fortunately, I redeemed myself by running another test–at least I think I did. The hot lead to the car battery was still connected, so instead of using chassis ground, I connected a jumper cable to the ground lead on the battery to extend to the driver’s seat. I knew that if I connected the horn switch lead to ground that the horn should sound as I complete the circuit through the battery bypassing the chassis. The horn still didn’t sound. I was trying to isolate the steering wheel switch from the clock spring by doing that test but unfortunately I can’t do it that way because the horn switch lead still goes through the clock spring. All roads in and out from the steering wheel go through the clock spring, including both ground and the horn switch.

As a last ditch effort, after watching this ChrisFix video about clock springs, I decided to test a theory. In his video, if he pointed the wheel all the way to the left, his horn began to work. I wanted to do the same test. Worst case scenario, I narrowed down the problem to one of a couple components–the steering wheel horn switch itself or the clock spring.

So when I was ready to leave for work the next morning, I decided to lock my steering wheel to the right and test as well as to the left. When I locked the steering wheel to the left, to my surprise, the horn worked. This gave me 99% confidence that the problem was the clock spring even though the airbag never stopped working. It also opened my eyes to ChrisFix auto repair videos, and with 8 million YouTube subscribers already, it seems like I was behind the 8 ball!

In researching the clock spring I came to find that they cost several hundred dollars! ChrisFix used an aftermarket clock spring to success, and in looking at what a clock spring does, I feel confident rolling the dice on an aftermarket unit. Worst case scenario is that the aftermarket unit uses cheaper materials and fails faster. If I keep the car long enough for that to happen, guess what, I already know how to replace the clock spring because I did it once before. I can choose at that time to either go OEM or get another aftermarket one.

I expect to get a replacement one within the next few weeks or so, but I am not planning on keeping Project CELICA off the road until then. However, I will probably drive much more passively until the horn gets back in working order!